Comprehensive CFO Solutions for Manufacturing Excellence

Your Trusted Manufacturing Finance Transformation Partner

At GroupOne.Us, we combine a robust suite of complementary advisory and consulting capabilities designed for manufacturing CFOs facing complex financial challenges.

Our integrated approach delivers comprehensive solutions for Financial Modeling, Process Optimization, Innovative Problem-Solving, and AI-powered strategic analysis tailored to manufacturing environments.

Analyze & Optimize Your Manufacturing Cost Structure

- ✓Proprietary Innovation Driver Trees (IDT)

Manufacturing-specific financial modeling tools

- ✓1,500+ Cost Nodes System

Identify optimization opportunities across your entire operation

- ✓Baseline, Forecast & Variance Tracking

Compare and analyze key metrics across your operation

- ✓Library of 50+ Specialized IDTs

Designed specifically for manufacturing finance

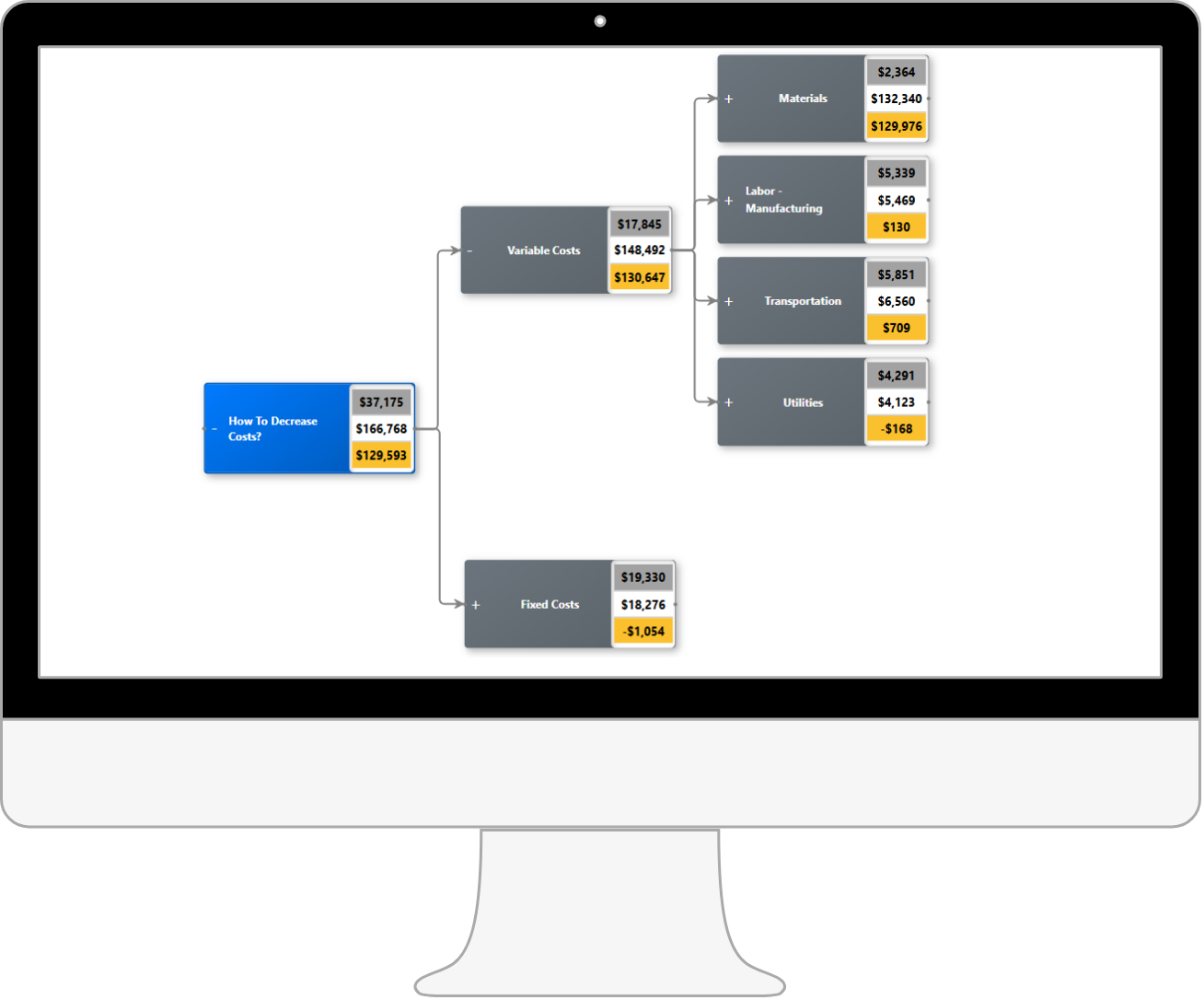

Detailed Financial Modeling Process

Comprehensive Cost Breakdown

Begin with a detailed breakdown of total costs by Variable and Fixed components

Strategic Impact Points

Navigate to specific endpoints where strategic changes will create maximum impact

Targeted Adjustments

Make targeted adjustments with clear visibility of baseline, forecast and variance impacts

Data-Driven Implementation

Implement changes with confidence through data-driven decision support

Detailed Financial Modeling Process

Usecase Step 1: Developing an Innovation Driver Tree (Financial Modeling)

- 1.Analyze Current Costs

- 2.Use Forecast2Cash.com for Decrease Current Costs exercise.

- 2.1.

Financial Modeling using Decrease Costs model in Forecast2Cash, which tracks costs by:

- •

Baseline

- •

Forecast

- •

Difference

- •

- 2.2.

Starts by the breakdown of total costs by Variable and Fixed components

- 2.3.

There are over 1,500 nodes/leaves, with only the last end-point available for data update, with the interim formulas for summing up.

- 2.4.

Determine at which endpoint you want to make changes.

- 2.5.

Here will work with Variable Costs > Materials

- 2.6.

Legend

- •

Top Grey is Baseline

- •

Middle White is Forecast

- •

Bottom Yellow is the difference, i.e., Baseline - Forecast

- •

Variance can also be Forecast - Baseline

- •

- 2.1.

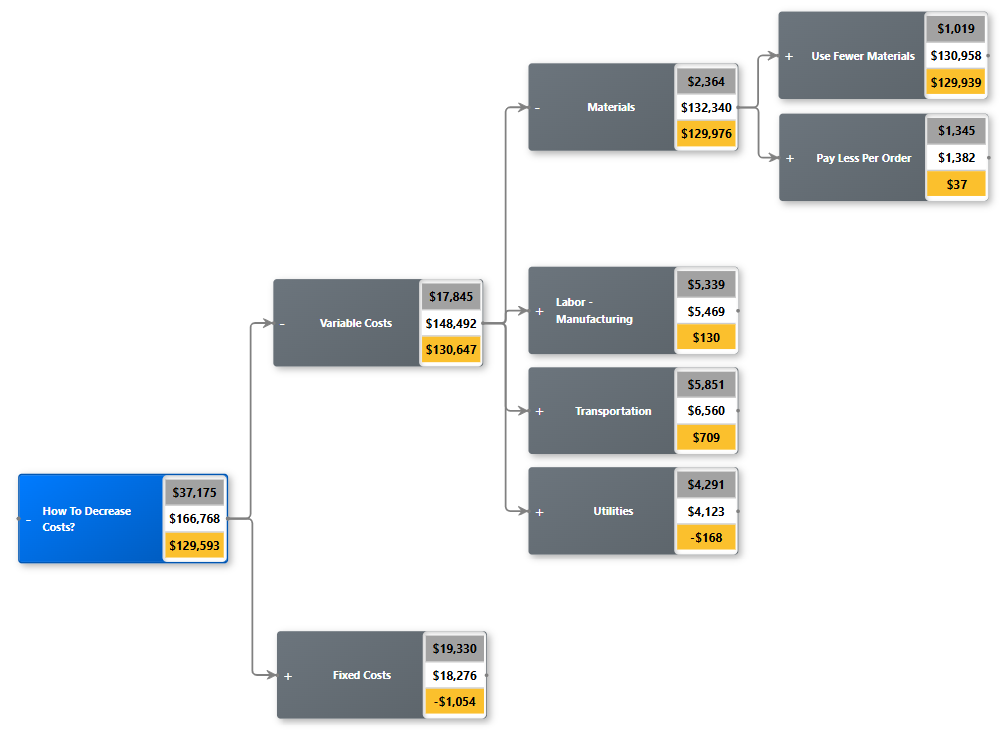

Material Cost Optimization Pathway

Follow the complete pathway from Variable Costs to actionable feature-level optimizations:

Variable Costs Breakdown

First Level: Variable Costs > Materials > Use Fewer Materials

Feature-Level Optimization

Second Level: Redesign Products > Reduce Features > Feature-Specific Optimizations

Color-Coded Visualization Legend

Strategic Process Optimization for Manufacturing Finance

Usecase Step 2: Accessing Cross-Functional Maps (CFPM) for step-by-step process changes

- ✓Manufacturing-Specific CFPMs

Leverage best practice process maps designed for manufacturing environments

- ✓Critical Intervention Points

Identify key intervention areas within Variable and Fixed cost structures

- ✓High-Level to Actionable

Drill down from categories like Materials to specific actionable endpoints

- ✓Extensive Process Library

Access over 1,000 CFPMs with ~1,000 process steps across ~100 process maps

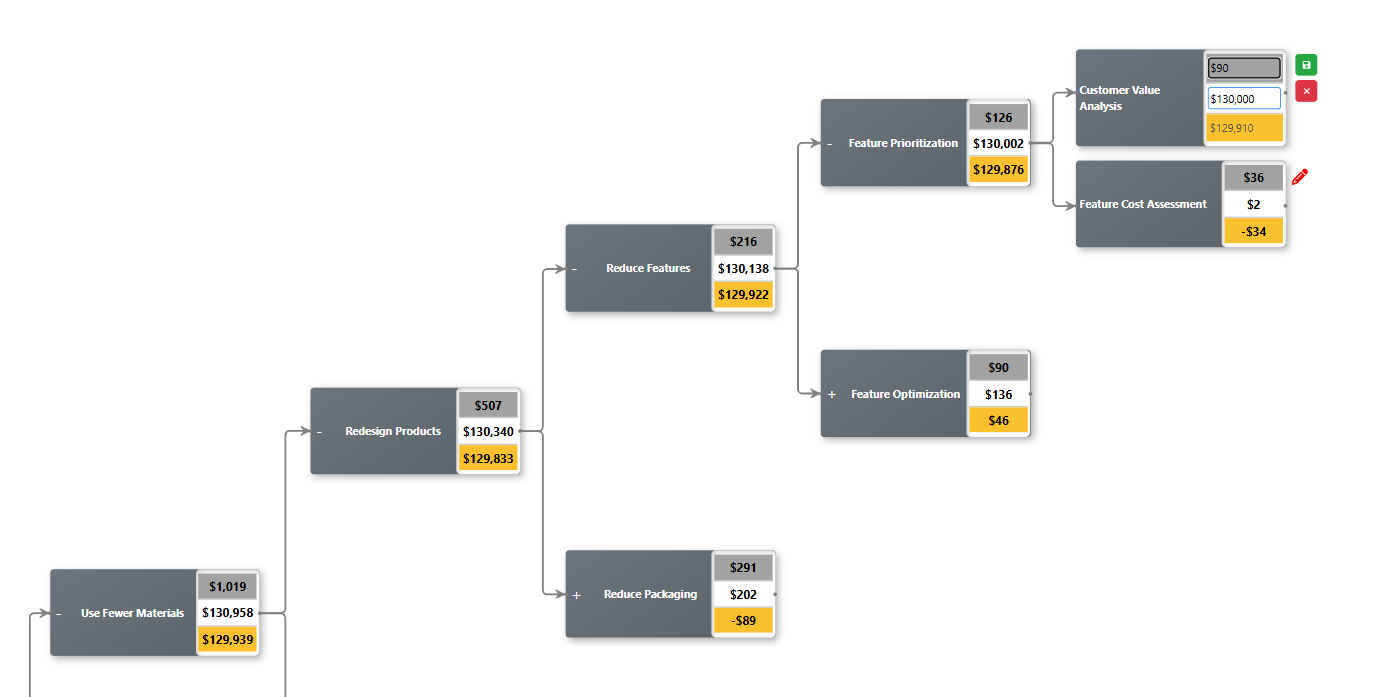

Process Map Example: Feature Optimization

a. Determine the endpoint/node where you want to make changes,

b. In the above case, we navigated to Variable Costs > Material > Use Fewer Materials > Redesign Products >Reduce Features to the following four nodes

- •Feature Prioritizations

- •Component Reduction

- •Feature Optimization

- •Design Simplification

c. Below are the four CFPM for the selected nodes:

d. Each CFPM shows Level 1 (L1) process maps, while the full system includes L1 to L3 processes with ~1,000 detailed steps across ~100 interconnected process maps.

Solving Complex Business Challenges with IdeaGens

Use IdeaGens for Complex Problem-Solving, Innovation & Collaboration

While Forecast2Cash and SAPModel are powerful for structured financial and process-driven cost reductions, not all challenges can be solved through heuristics, technical tools, or linear decision-making.

Some business problems are complex, involving:

Interdependent factors with no clear cause-effect relationship

Unpredictable financial and operational risks

Conflicting stakeholder priorities

This is where IdeaGens excels.

- ✓Foster creativity

Move beyond standard cost-cutting and uncover innovative financial strategies.

- ✓Leverage collaboration

Engage stakeholders across finance, operations, and strategy teams to generate well-rounded solutions.

- ✓Solve strategic uncertainties

Use a proprietary 3-Phase, 6-Step process to navigate and resolve multi-dimensional financial challenges.

IdeaGens' 3-Phase / 6-Step Process:

Phase 1: Understand & Analyze the Problem

1️⃣ Initial Analysis – Identify key cost drivers and inefficiencies.

2️⃣ Cause & Effect Analysis – Uncover hidden financial and operational interdependencies.

Phase 2: Generate & Assess Solutions

3️⃣ Ideation – Brainstorm cost-saving opportunities and alternative financial strategies.

4️⃣ Decision Analysis – Assess trade-offs and rank the best financial interventions.

Phase 3: Implement & Monitor Solutions

5️⃣ Unintended Consequences Analysis – Predict risks and secondary effects of cost-reduction measures.

6️⃣ Implementation Analysis – Ensure strategic alignment and measure financial impact.

How IdeaGens Enhances Manufacturing CFO Decision-Making

✅ Beyond Traditional Cost-Cutting: Instead of just eliminating costs, IdeaGens helps CFOs explore alternative revenue models, pricing strategies, and financial innovations.

✅ Risk-Aware Strategy Execution: Prevents cost-cutting pitfalls by assessing long-term impact and unintended consequences.

✅ Data-Driven, Yet Creative: Balances quantitative financial models (Forecast2Cash) with qualitative, strategic insights.

Usecase Step 3: Use Creativity to find genuinely innovative solutions

Example: Reshaping Cost Strategy Through Innovation

Instead of just reducing Material Costs, IdeaGens might reveal an alternative strategy:

Leverage supplier co-innovation

to reduce component costs

Develop new revenue streams

via premium product differentiation

Enhance sustainability measures

for long-term financial and brand value

Ready to Transform Your Manufacturing Finance Operations?

Schedule a consultation with our manufacturing finance experts to discuss your specific challenges and discover how our comprehensive solutions can help.

Select a convenient time from our calendar, and we'll be in touch to confirm your appointment.

Loading calendar...